We guarantee timeliness and precision with our Waterjet cutting services for Glass

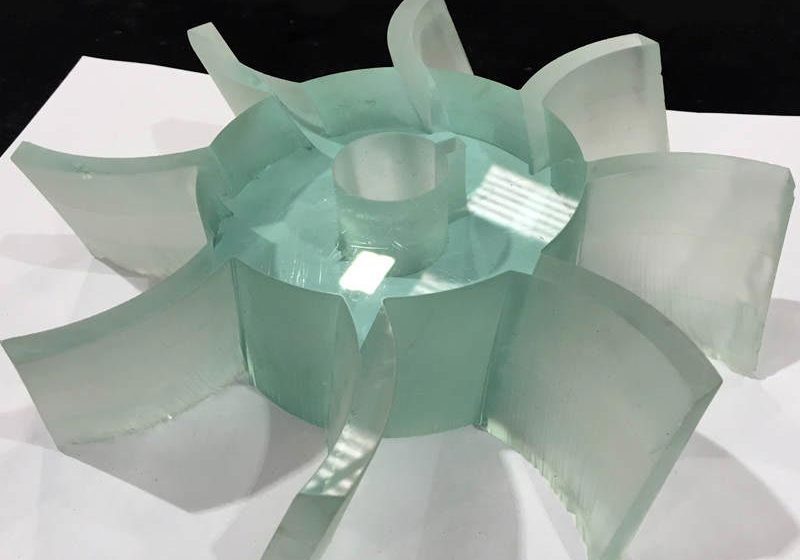

Waterjet cutting uses water and an abrasive to cut through glass along a preset path for glass cut to size or so you can create intricate shapes or parts unique to your project.

Waterjet technology cuts without heat or distortion which allows for a range of options such as:

- cutting stained glass

- piercing holes in glass

- cutting laminated glass

With waterjet glass cutting there is less waste for glass cut to size because there is no need to etch and break. We use omni-directional cutting, even at tight inside corners. Plus the power of the waterjet allows for single-pass cutting, depending on material thickness.

There is also no need for extensive clamping, so there is less vertical force or chance for breakage.

Whether you need to cut glass sheets or tiny detailed shapes we can help!

See the other materials we can cut and learn more about how waterjet cutting works here.

Glass Cutting Comparisons

| WaterJet | Laser | Plasma | |

| Cuts non-metallic materials | Yes | No | No |

| Capable of multi-head cutting applications | Yes | No | Limited |

| Multilayer cutting | Yes | No | No |

| Easily cuts composites | Yes | No | No |

| Causes material hardening | No | Yes | Yes |

| Causes burr formation | None or minimal | Yes | Yes |

| Requires re-working | None or minimal | Yes | Yes |

| Loss of material | None or minimal | High | Yes |

| Tightest tolerances | .004" - .011" (0.1 - 0.3mm) | .004" (0.1mm) | .008" - .019" (0.2 - 0.5mm) |

| Creates hazardous vapors | No | Yes | Yes |

| Maximum material thickness's cut | Up to 12" (305mm) | < .98" (25mm) | < 3.15" (80mm) |

| Causes warping/deformation to material | No | Yes | Yes |