We guarantee timeliness and precision with our Waterjet cutting services.

Waterjet cutting uses water and an abrasive to erode material along a programmed path. Waterjet technology cuts without heat or material distortion, enabling us to cut materials of almost any kind with exceptional precision to create shapes or parts unique to your project.

We can also cut a wide range of other materials including:

- Ceramics

- Aluminium

- Acrylic

- Bullet-proof glass

- Carbon Fiber

- Composites

- Fiberglass

- Foam

- Gasket materials

- Granite

- Kevlar

- Wood

- Laminates

- Marble

- Nylon

- Plastics

- Polycarbonate

- Rubber

How Waterjet Technology Works

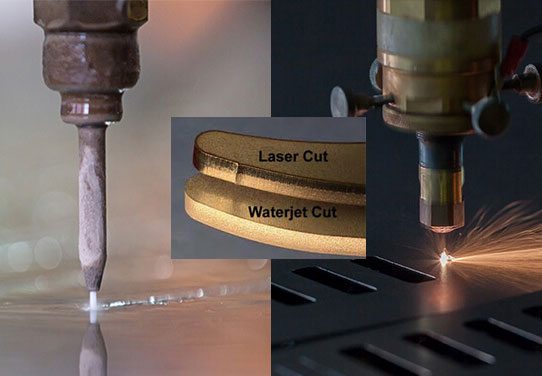

Abrasive waterjet cuts materials that evade laser technology, as the process does not require materials to be exposed to heat. This removes the risk of thermal distortion or hardening of the material.

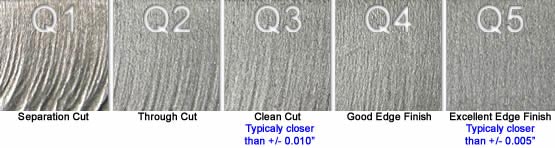

Jet Cut Solutions uses the latest technology from Europe to digitally scan large format and odd shaped templates to within +/- 0.03mm. Our cutting technology is five times faster than wire electrical discharge machining (EDM) and other conventional cutting methods. It has a bigger work area which allows large format materials to be cut in one set up, resulting in time and cost savings for our clients.

Our machine has the ability to cut both conductive and non-conductive materials. Multi axis, heat free cutting prevents the rough edges that often result from flame or plasma cutting, and enables angles up to 60 degrees for bevelled edges and countersinks. The versatility and precision of waterjet removes the need for a secondary option, or another machine, to complete the procedure.

5-axis cutting gives us the flexibility to cut angles up to 60° from vertical position This is especially helpful when the material is extremely hard or the bulk of material is removed for another process, such as building components or precision parts.

The aerospace industry also uses abrasive Waterjet cutting for several steel cutting solutions such as aluminium, brass, inconel, and other exotic metals.

This waterjet application is used in the aerospace industry for cutting composites, brake components, wing sections, turbine blades, landing gear, and many other parts.

Whether you source the material or we supply it for you, we provide a cost effective solutions with outstanding results.

Cutting Comparisons

| WaterJet | Laser | Plasma | |

| Cuts non-metallic materials | Yes | No | No |

| Capable of multi-head cutting applications | Yes | No | Limited |

| Multilayer cutting | Yes | No | No |

| Easily cuts composites | Yes | No | No |

| Causes material hardening | No | Yes | Yes |

| Causes burr formation | None or minimal | Yes | Yes |

| Requires re-working | None or minimal | Yes | Yes |

| Loss of material | None or minimal | High | Yes |

| Tightest tolerances | .004" - .011" (0.1 - 0.3mm) | .004" (0.1mm) | .008" - .019" (0.2 - 0.5mm) |

| Creates hazardous vapors | No | Yes | Yes |

| Maximum material thickness's cut | Up to 12" (305mm) | < .98" (25mm) | < 3.15" (80mm) |

| Causes warping/deformation to material | No | Yes | Yes |